We bring you the best possible AI applications for your industry.

Fovea EDGE Product Line.

Fovea EDGE Advantage

Edge products bringing real-time inference on the shop-floor, to enable automation.

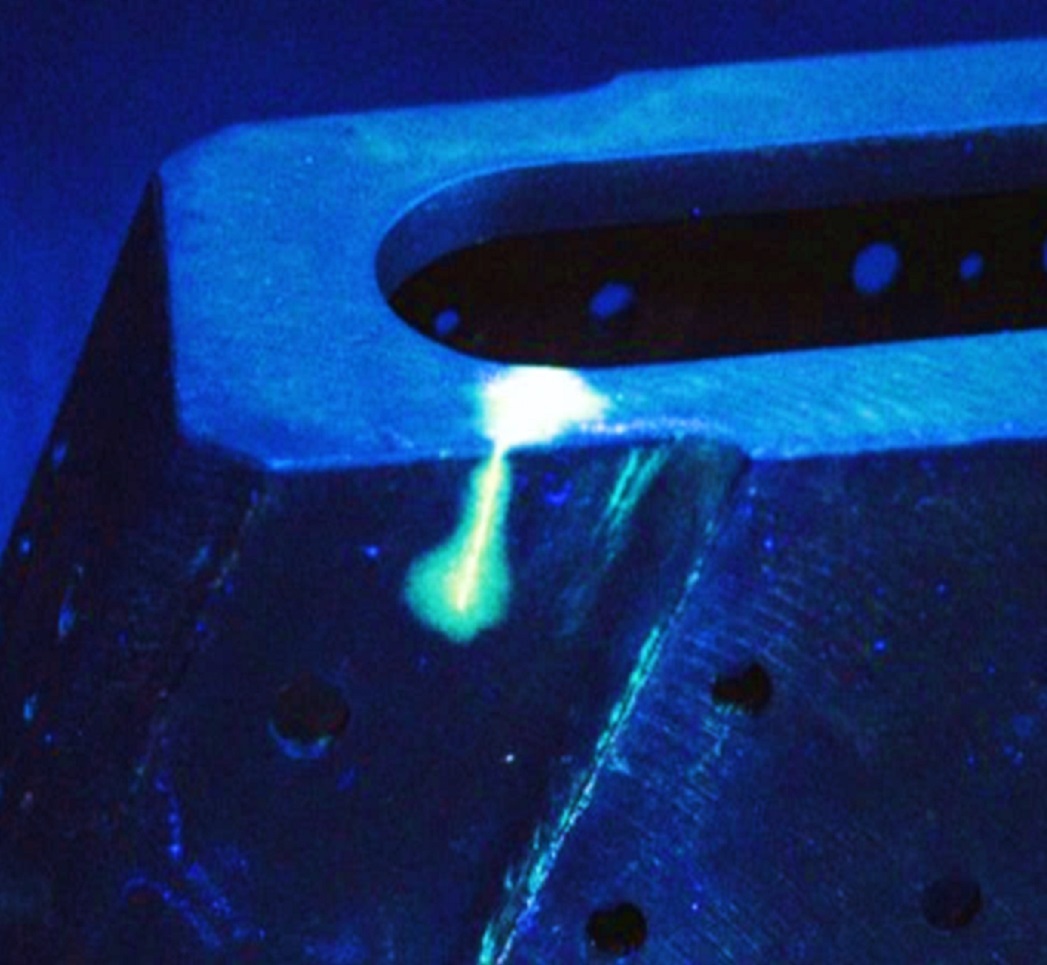

Product Demonstration.

Watch the demo video to see the Fovea EDGE suite of solutions for Fluorescent penetrant inspection (FPI) in action.